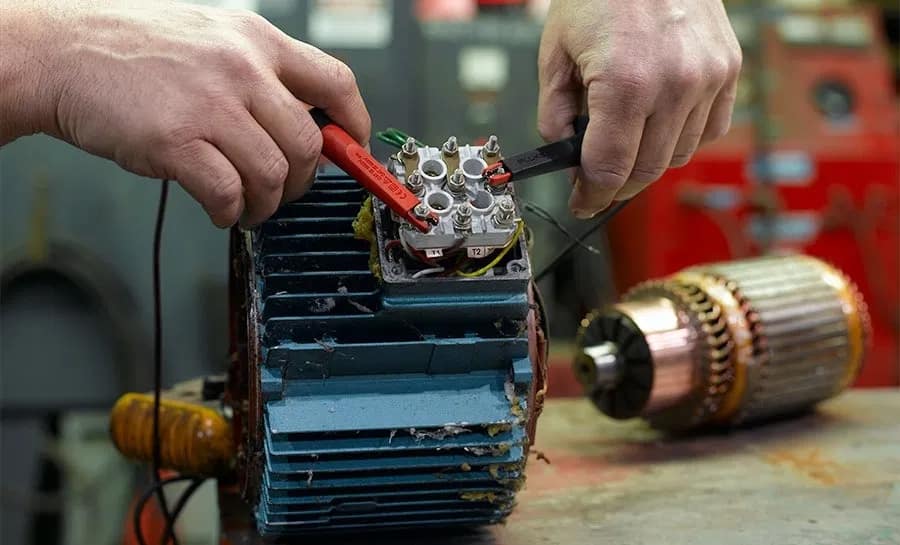

Motor Repairs

Motors are the heart of the fans, compressors, and other moving parts in HVAC systems. Motor failures can cause system downtime and inefficiency.

1. Repair vs Replacement:

-

Repair:

-

If the motor is overheating, it could just need cleaning, lubrication, or a reduction in load.

-

Brush replacement (for older motors) or bearing lubrication might solve some issues.

-

-

Replacement:

-

If the motor burns out, short-circuits, or suffers irreparable electrical damage, replacing the motor is typically the best option.

-

If the motor is inefficient, upgrading to a higher-efficiency motor can improve system performance and reduce energy costs.

-

2.Repair Process:

-

Disconnect and Remove the Motor: Disconnect the motor from the system and remove it from the fan or compressor.

-

Install New Motor: Install the new motor, ensuring proper alignment and electrical connections.

-

Test: Run the motor through operational tests to ensure it performs at optimal efficiency.

3. Replacement Process:

-

Removal of Old Pipe: Carefully remove the damaged heat pipe.

-

Install New Heat Pipe: Position and connect the new heat pipe to the existing system.

-

Re-charge Fluid: Ensure that the new system is properly charged with the required heat transfer medium.

-

Testing: Perform tests to check for efficient heat transfer and operational performance.