Pump Services

Pumps are integral components used in a wide variety of applications, ranging from HVAC systems, industrial processes, water treatment, and oil & gas operations, to agriculture and municipal services. The supply and service of pumps encompass the provision, installation, maintenance, repair, and upgrading of various types of pumps to ensure optimal performance, energy efficiency, and longevity.

1. Supply of Pumps

Pumps are classified by the type of fluid they handle and their application. The main types of pumps supplied include:

-

Centrifugal Pumps: Used in HVAC systems, water treatment plants, and industrial processes. Ideal for transporting water and other liquids.

-

Applications: Circulation, cooling systems, water transfer.

-

-

Positive Displacement Pumps: Move a fixed amount of fluid per cycle, ideal for viscous liquids or precise flow control.

-

Applications: Oil & gas, chemical processing, food & beverage.

-

-

Gear Pumps: Used for high-viscosity fluids, commonly found in lubrication, hydraulic, and fuel systems.

-

Applications: Lubrication, oil transfer, hydraulic systems.

-

-

Diaphragm Pumps: Known for handling corrosive or hazardous fluids, used in chemical and pharmaceutical industries.

-

Applications: Chemical transfer, sludge handling, hazardous material transport.

-

-

Peristaltic Pumps: For pumping slurries, viscous fluids, and shear-sensitive liquids.

-

Applications: Food processing, pharmaceutical, chemical industries.

-

-

Screw Pumps: A type of positive displacement pump for high pressure and low/moderate flow.

-

Applications: Wastewater, oil & gas, chemical handling.

-

-

Submersible Pumps: For pumping water from wells, sewage, and stormwater management.

-

Applications: Draining, well pumps, sewage.

-

-

Solar-Powered Pumps: Used in remote areas for water supply, irrigation, and other off-grid applications.

-

Applications: Irrigation, rural water supply, remote operations.

-

Key Pump Supply Services:

-

Consultation and design: Application needs analysis and pump recommendation.

-

Procurement: Supplying pumps from reputable manufacturers.

-

Customization: Designing pumps to meet specific needs.

-

Installation: Professional installation, alignment, motor coupling, piping, and controls.

2. Pump Installation Services

Proper installation is crucial for pump efficiency and longevity, including:

-

Site assessment

-

Secure and properly aligned mounting

-

Suction/discharge piping installation

-

Electrical wiring

-

Vibration/noise/flow/pressure/performance testing

3. Pump Maintenance Services

-

Regular maintenance is essential for efficient, long-service operation:

-

Lubrication of oil/bearings

-

Cleaning filters, impellers, and components

-

Vibration monitoring

-

Seal inspection and replacement

-

Pressure and flow checks and calibration

-

Electrical system checks

Types of preventive maintenance:

-

Routine inspections

-

Performance analysis and efficiency monitoring

-

Cleaning of casing, impeller, components

-

Timely part replacement

-

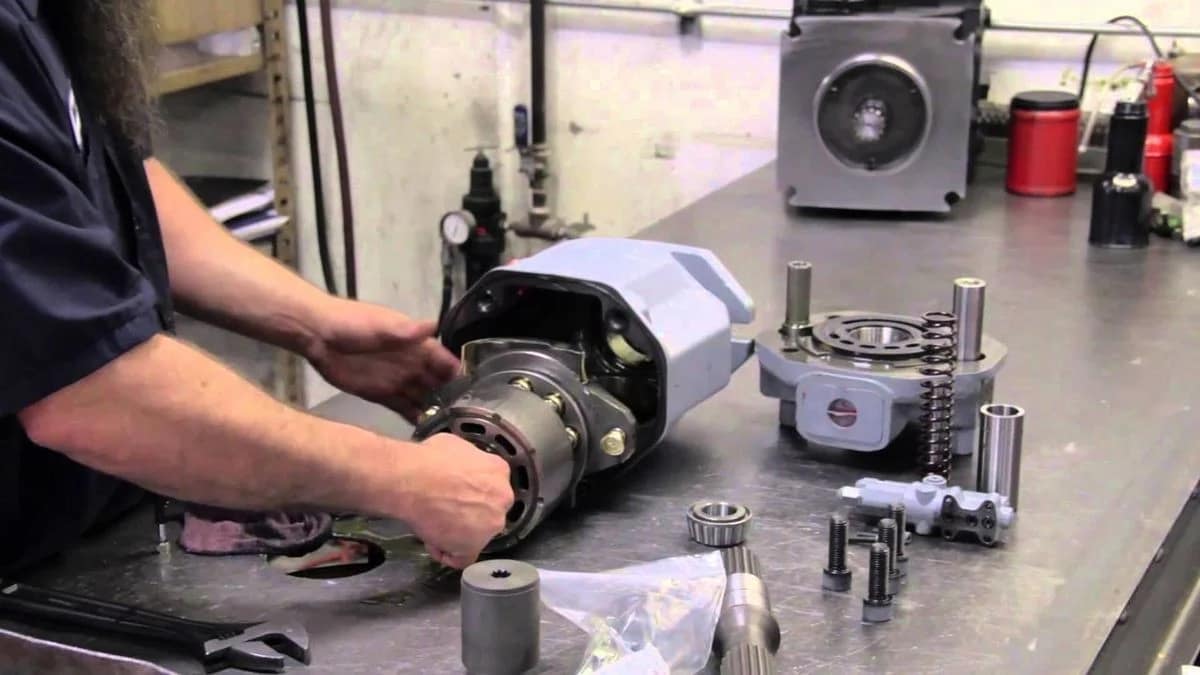

4. Pump Repair Services

Prompt & effective repair minimizes downtime. Common repairs include:

-

Mechanical: Bearing replacement, impeller repair/replacement, shaft alignment.

-

Seal/gasket replacement for leaks or loss of pressure.

-

Electrical: Motor rewinding, control panel troubleshooting, fixing relays/switches.

-

Cavitation and corrosion repairs.

Repair Process:

-

Diagnostic evaluation and testing

-

Disassembly and inspection

-

Damaged component replacement (OEM quality)

-

Reassembly and thorough performance testing

-

Post-repair monitoring

5. Pump Upgrades and Modernization

Upgrades and modernization provide long-term benefits:

-

Energy-efficient motors

-

Variable Frequency Drives (VFDs) for speed/energy control

-

Advanced control systems (smart controls and sensors)

-

Corrosion-resistant materials and part upgrades