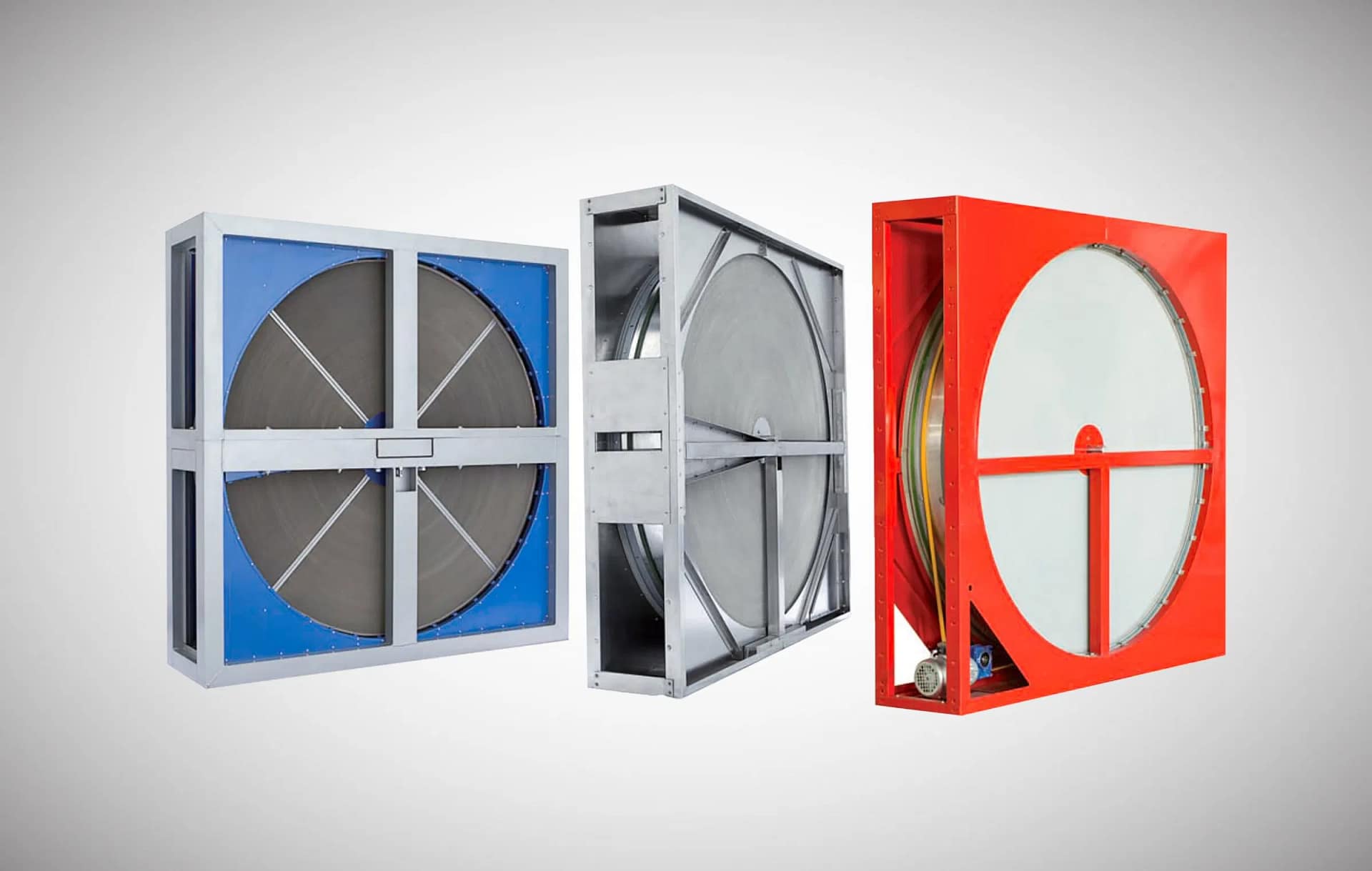

Heat Recovery Wheel Repair

The Heat Recovery Wheel is a key energy-saving component that transfers heat between the exhaust and intake air streams, reducing the energy load on the HVAC system.

1. Repair vs Replacement:

-

Repair:

-

If the wheel is dirty causing reduced efficiency, cleaning and maintenance can restore it to full functionality.

-

If the bearings or seals are worn out, they can typically be replaced or lubricated.

-

Minor structural damage (such as dents or cracks) can often be repaired with special bonding agents or welding, depending on the wheel’s material.

-

-

Replacement:

-

If the wheel’s material (e.g., aluminum, desiccant, or silica gel) is degraded and unable to transfer heat effectively, replacement is typically required.

-

If the wheel is severely damaged, such as cracks, warping, or major leaks, it may be more cost-effective to replace it.

-

If repairs are frequent or costly, replacing the unit might be more economical long-term.

-

Repair Process:

2. Repair Process:

-

Inspection: Check for damage, dirt, and wear on the wheel, bearings, and seals.

-

Cleaning: Clean the wheel and internal components, removing dirt, mold, and scale buildup.

-

Seal/Bearing Replacement: Replace worn seals or bearings to ensure proper rotation.

-

Re-balance and Test: After repairs, balance the wheel and perform operational tests to verify performance.

3. Replacement Process:

-

Removal of Old Unit: Remove the damaged or old heat recovery wheel.

-

Install New HRW: Place the new wheel and ensure proper alignment with the casing and seals.

-

Rebalance and Test: Ensure that the new HRW is running smoothly, without excessive vibrations, and perform operational tests.